Published: 11/19/2020

(Akron, Ohio) – Smithers, a leading provider of testing, consulting, information, and compliance services, has invested in upgraded testing instrumentation and equipment at its

rubber chemical and

physical testing laboratories in Akron, Ohio.

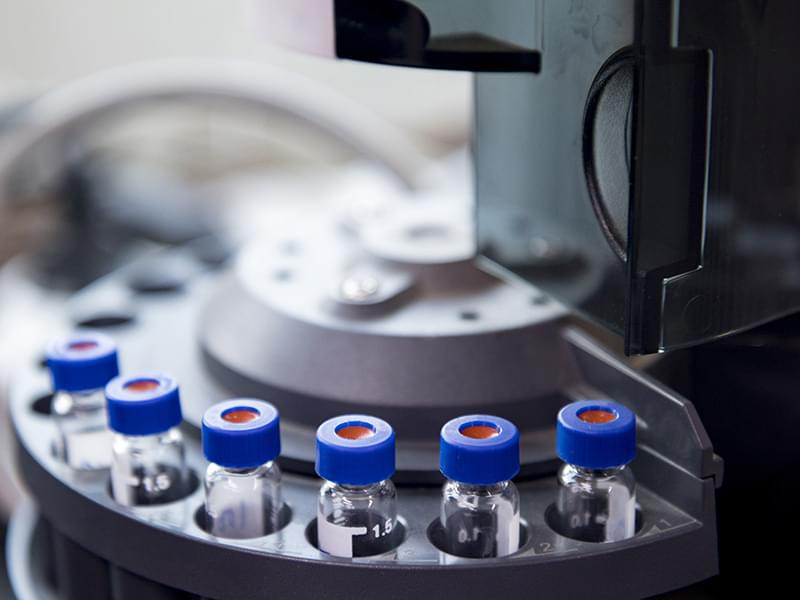

With these new instruments, Smithers has expanded its testing capabilities in the area of pyrolysis

gas chromatography-mass spectrometry (Py-GC/MS). Pyrolysis GC/MS can be used to analyze samples that cannot be analyzed by GC-MS alone due to volatility limitations.

“Pyrolysis GC-MS is designed to analyze whole

rubber and plastic products quickly and provide a comprehensive composition analysis—plasticizers, additives, polymers—all at once. With our double-shot pyrolyzer, we can also focus in on specific components using techniques such as thermal desorption or heart cutting analysis. Whether you are looking at

basic composition or

material failure, pyrolysis techniques are highly versatile and provide a huge amount of information quickly. We are delivering a larger portfolio of both qualitative and quantitative analyses to our clients,” said Dr. Dustin Jenkins, Chemistry Supervisor, Materials Science and Engineering, Smithers. “We can analyze silicone rubbers, plastics, polyamides, and virtually any other material, in addition to the materials we can analyze with our existing traditional GC-MS capabilities.”

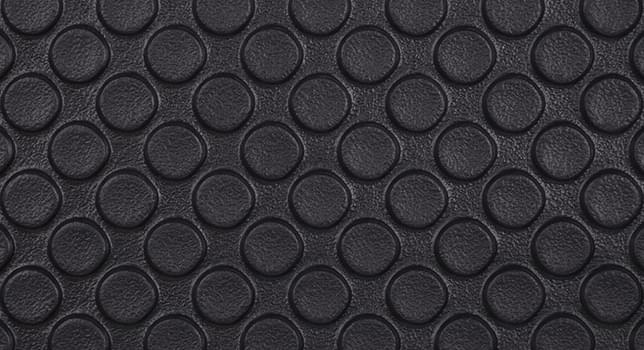

Smithers also invested in an upgraded rubber process analyzer (RPA). The new instrument can be used to measure the dynamic properties of cured and uncured rubber materials and raw polymers as well as polymer compounds. Its capabilities include cure tests, sweep tests, stress relaxation tests, raw

polymer characterization, torque measurement, and more. The instrument is qualified to test to a variety of industry specifications, including ASTM D5289, D6048, D6204, D6601, D7050, D8059, and D7605.

“This new instrument offers excellent temperature controls and higher resolution within the extended dynamic range (EDR), which allows us to see changes in material properties at lower strains during a strain sweep test, which is especially helpful when testing silica-filled materials, such as tire treads,” said Christine Domer, General Manager, Akron Labs, Smithers. “Ultimately, this investment supports our commitment to precise testing data for our clients.”

Earlier this year, Smithers announced

an upgrade to an automated low temperature retraction instrument to enhance capabilities in its physical testing laboratory. The new instrument offers improved temperature control for low temperature retraction and, with the automation, is significantly more efficient, which allows for better turnaround times for customers.

Located in Akron, the Smithers

rubber testing laboratory offers a full suite of material testing, chemical analysis, and sample preparation services for clients across a number of industry segments. The lab shares space with the company’s product testing laboratory and has a sister lab in the United Kingdom. The combination of the two locations and other complementary labs in North America, Europe, and China gives Smithers the capacity, flexibility, and expertise to meet any client’s testing needs worldwide.

To learn more, get in touch with Jeremy Elliott at 330-762-7441 or

jelliott@smithers.com.

####

About Smithers:

Founded in 1925 and headquartered in Akron, Ohio, Smithers is a multinational provider of testing, consulting, information, and compliance services. With laboratories and operations in North America, Europe, and Asia, Smithers supports customers in the transportation, life science, packaging, materials, components, consumer, and energy industries. Smithers delivers accurate data, on time, with high touch, by integrating science, technology, and business expertise, so customers can innovate with confidence.