High-speed cleat testing is an essential step in the tire validation process as it relates to understanding vehicle dynamics and road interactions. By simulating real-world conditions and pushing tires to their limits, engineers can gather accurate data and identify areas for improvement in tire design. This not only results in higher consumer satisfaction but also allows for the optimization of manufacturing processes to ensure consistent and high-quality production.

We spoke to Smithers Tire & Wheel Test Laboratory Technical Director Cliff Hodges, to learn more about this essential piece of the tire testing puzzle.

What data does cleat testing provide?

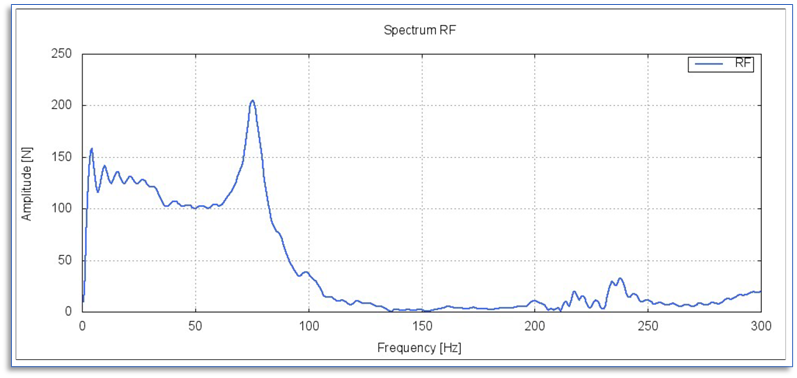

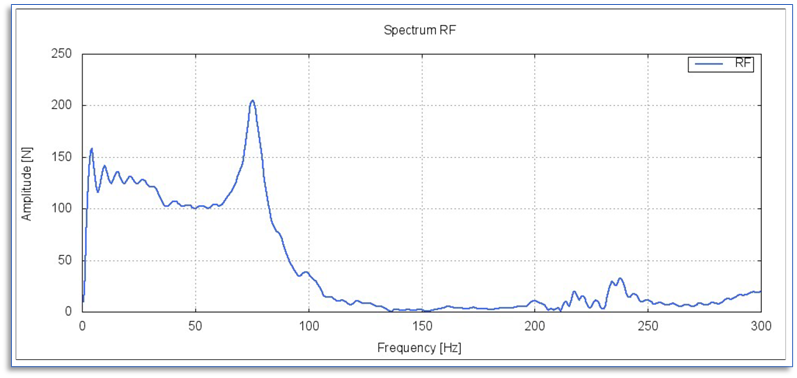

High-Speed cleat data is used in models to identify and parameterize the tires response to low amplitude/high frequency impacts. In addition to evaluating the peak forces being transmitted into the chassis (time domain), data can be visualized in the frequency domain, where tire modes can be identified.

Can you go into the details on what this testing entails?

In addition to utilizing the SAE J2730 testing protocol, test steps can be catered to the customer’s request. Different customizations can be made to the test matrix as well as the hardware, such as cleat sizes and shapes, to fit customer requirements. Test matrices can also be modified to suit customer requirements. For example, commercially available tire models require only 3 speeds to quantify the model parameters, but Smithers can modify the speed inputs based on continuously increasing model fitting capabilities (up to 130kph). Post-processing methods can be customized, allowing customers to get exactly what they want in different available formats.

Why is cleat testing useful in tire models?

Models are used to provide accurate mathematical representations of the tire’s response to static or dynamic

positional inputs. Tire models are then used by vehicle dynamics solvers and simulations to predict how the vehicle will respond with prescribed driver inputs (e.g.. accelerating, braking, steering, etc). Commercially available tire models include not only handling maneuvers but the tire’s impact response to better predict the vehicle's response in broader conditions. Additionally, impact response is used in chassis development, predicting the loads being transmitted as well as ensuring suspension and tire modes do not align and cause resonance into the cabin. This can alleviate noise, ride, and comfort issues for the driver. With the increase in EV platforms, tire noise and resonance have become one of the targeted areas for improvement in driver comfort. (also termed as ride-and-comfort).

Are there specific advantages to the technology solution that Smithers operates?

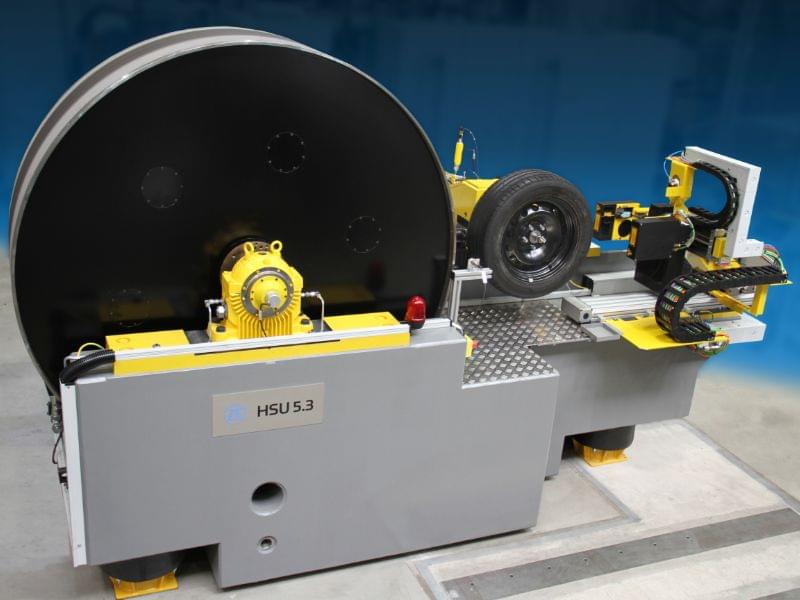

ZF manufactured this machine to be very rigid and stiff, with the first order machine mode at 350Hz. First order tire modes (depending on the pressure and load) generally fall between 20-80Hz. Therefore, noise contamination is reduced in the dataset. Furthermore, raw machine sampling rates are around 200KHz, capturing critical data through the impact zone and removing the possibility of signal aliasing at higher frequencies (down sampling is performed in HSC format to reduce data file size).

.png?lang=en-US)

.png?lang=en-US)

.png?lang=en-US)

What are some other applications that can benefit from the Smithers HSU machine?

In addition to cleat response, the machine can measure high-speed and low-speed uniformity. HSU and LSU can be coupled with flat-spotting protocols. Flat spotting is a condition where tires develop a temporary or sometimes permanent deformation due to prolonged stationary pressure. Essentially, flat spotting uses oven aging, either short term or long term while temperatures exceed 100 °F, mounted on fixtures meant to simulate a static tire on a vehicle. Tires are then removed, and HSU or LSU test methods are used to measure radial, lateral, and tangential force variations. These measurements quantify variation amplitude at multiple tire harmonics to compare to what the driver may experience under those conditions.

The benefits we’ve seen is not only the increase in data quality, but it also enables us to expand our service line offerings (HSU, LSU, tire noise, flat-spotting, etc). In addition, it has enabled Smithers to become a one-stop-shop for all tire testing needs across all sizes and designs, including motorsports.

Essentially, this machine is very versatile in its applications to support tire and vehicle OEMs

To learn more about our HSU machine or to discuss a testing project, contact Cliff Hodges, Technical Director, Tire and Wheel Testing at chodges@smithers.com.

.png?lang=en-US)

.png?lang=en-US)

.png?lang=en-US)